Computational Materials Engineering

ICME - Systems Level

Ultimately, the value of ICME is derived from the ability to combine a variety of approaches and predict system level performance. By utilizing a holistic, multiphyisics approach, we can provide the most accurate prediction of material properties, processing effects, component behavior, and full system performance.

Gas turbines

Hypersonic thermal protection systems and thermal transport

Rocket engines

Radomes, windows, and apertures

ICME - Areas of Interest

HAMR is looking for collaborators in the following areas:

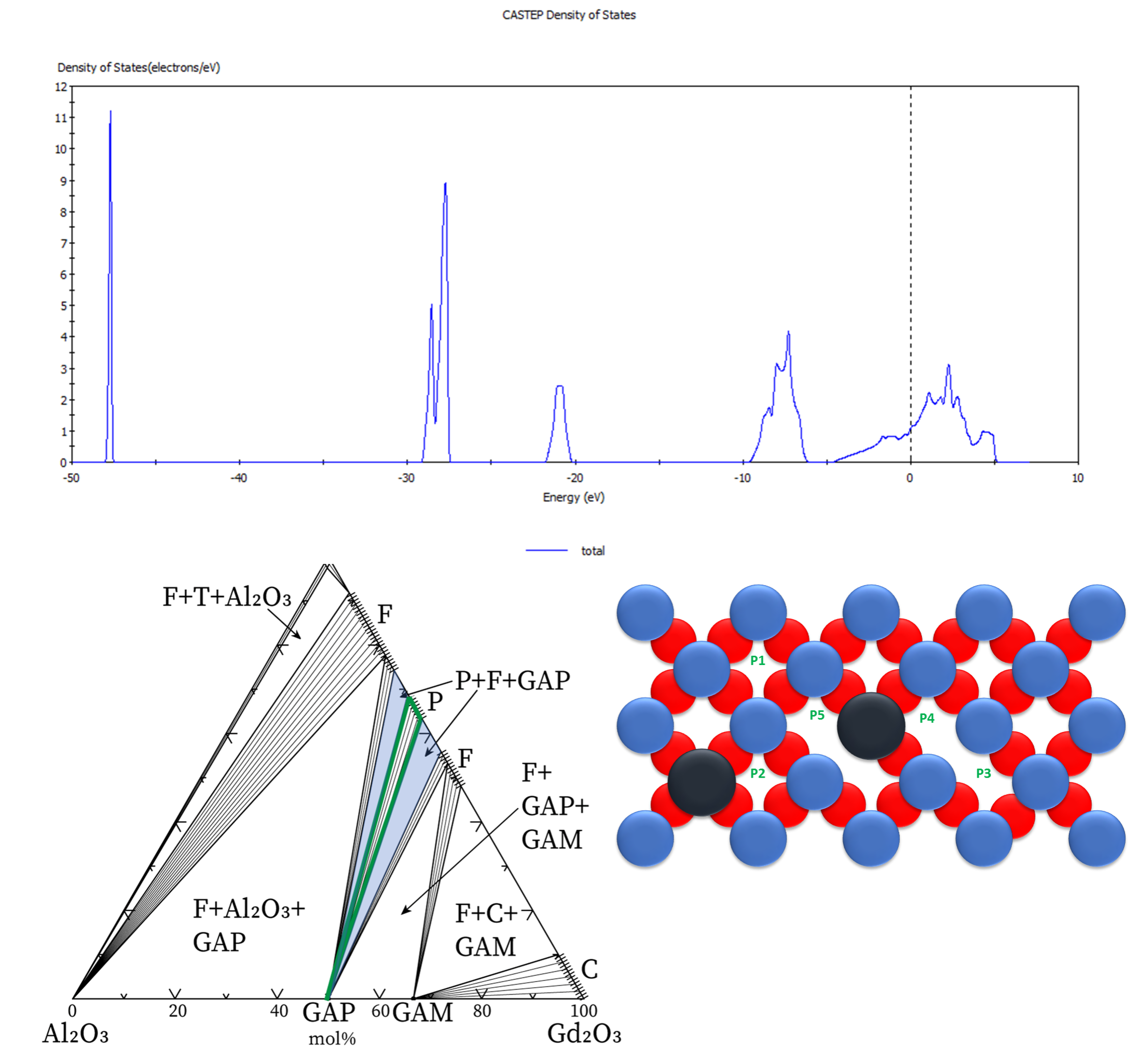

Ab-Initio

Diffusivity, thermomechanical property predictions for small systems

Refractory HEA/CCA property predictions

MC/MD

Diffusivity, thermomechanical property predictions for large systems

Oxidation, volatility, morphological changes

SEI and battery interfaces

Continuum (CALPHAD, CFD)

CMAS degradation in T/EBCs

Heat transfer (hypersonics, gas turbines, rocket nozzles)

ICME - Areas of Expertise

Computational materials engineering is a key facet in the development of each and every technology at HAMR Industries. We recognize the value of combining the length and times scales of various modeling and simulation techniques to connect fundamental material properties and processing effects. Together, these help us predict the resultant structures and component performance, enabling a rapid and efficient developmental cycle. Our team is experienced in the following areas:

Micromechanics (FEM)

Object oriented finite element for structure-based thermomechanical simulations

Cold spray particle deposition and coating property evaluation

Thermal cycling, erosion, and thermal conductivity simulations of thermal & environmental carrier coatings and CMCs

Fragmentation

Mesoscale (FEM, semi-analytical)

Non-linear optical modeling of photonic structures via COMSOL and semi-analytical methods

Custom-built FEM solver for evaluation of RF performance in radomes, windows, and apertures